Boom Loader Arm Repairing Services

Boom Loader Arm Repairing Services Specification

- Location

- On-Site

- Custom Fabrication Support

- Available

- Brand Compatibility

- Universal / As per Client Requirement

- Repair Technique

- Welding, Alignment, Refurbishment

- Skill Level

- Highly Skilled Professionals

- Service Duration

- Depends on Repair Scope

- Material Procurement

- Customer End

- Usage/Application

- Construction Equipment

- Machine Downtime Minimization

- Ensured

- Response Time

- Immediate/Within Scheduled Date

- Documentation Provided

- Repair Report & Warranty Details

- Service Warranty

- Yes (As Per Terms)

- Quality Assurance

- Standardized Testing Post Repair

- Service Mode

- Offline

- Service Type

- Boom Loader Arm Repairing Services

- After-Sales Support

- Yes

- Safety Compliance

- Followed as per Industry Norms

About Boom Loader Arm Repairing Services

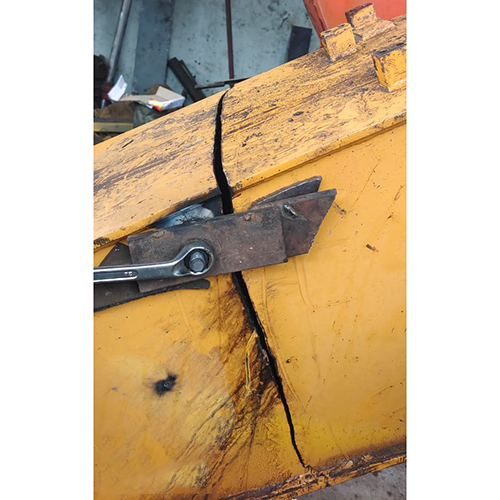

Comprehensive Boom Loader Arm Repair Solutions

Our service covers all types of boom loader arms, offering everything from precise welding to expert alignment and refurbishment. Whether your equipment brand is specified or unique, we cater to universal and custom requirements using advanced repair methods. Our objective is to restore optimal functionality, extend equipment lifecycle, and enhance safety on your construction site.

On-Site, Skilled, and Efficient Repairs

Our highly trained repair technicians provide on-site services anywhere in India, ensuring immediate response or repairs within your scheduled timeline. By deploying experienced professionals equipped with industry-leading tools, we guarantee machine downtime is minimized, helping you maintain seamless construction operations.

Quality Assurance, Documentation, and Warranty

We emphasize quality through standardized post-repair testing and strict adherence to industry safety norms. Each service is accompanied by comprehensive documentation, including a repair report and warranty details tailored to our terms. Our after-sales support ensures you have ongoing assistance even after the repair is complete.

FAQ's of Boom Loader Arm Repairing Services:

Q: How do you ensure compatibility with different boom loader brands during repairs?

A: Our Boom Loader Arm Repairing Services are designed for universal compatibility. We assess the specific requirements of your equipment and provide custom solutions when necessary, ensuring repairs align with the original manufacturer's standards.Q: What repair techniques are used and what are their benefits?

A: We utilize advanced welding, precise alignment, and thorough refurbishment techniques. These methods restore structural integrity, optimize performance, and ensure long-term durability of your boom loader arm.Q: When and where are the repair services provided?

A: Repairs are conducted on-site, directly at your location anywhere in India. Our team responds immediately or within your preferred schedule, minimizing transportation needs and reducing machine downtime.Q: What is the repair process for a boom loader arm?

A: After initial assessment, our professionals perform required welding, alignment, or refurbishment, followed by standardized testing. We also offer custom fabrication if needed. All services adhere to industry safety standards.Q: Is there any warranty or documentation provided after repair?

A: Yes, we provide a detailed repair report and warranty coverage as per our terms. This documentation includes the scope of repairs and guarantees quality assurance.Q: How does the service benefit construction equipment operators?

A: Operators gain from minimized machine downtime, rapid on-site service, enhanced equipment reliability, and comprehensive after-sales support, which ensures their machinery remains in top condition.Q: What support is available after the repair is completed?

A: We offer ongoing after-sales support to address any concerns or further service needs, ensuring your construction operations continue smoothly post-repair.- Core Services: Comprehensive hydraulic, electrical, mechanical, and structural repairs for boom lifts, loaders, and earthmoving machinery.

- Key Features:

- Diagnostic & Repair: Expert identification and fixing of complex mechanical issues.

- Preventative Maintenance: Regular inspections, lubrication, and fluid checks to extend equipment life.

- On-site/Workshop Support: Flexible, fast-response services at your site or dedicated service centers.

- Genuine Parts: Use of high-quality replacement parts for reliability.

- Applications: Construction, infrastructure development, and mining projects.

- Benefits: Minimized downtime, enhanced safety, and cost-effective operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry